Back

Learning the trade from a master jeweler

My first week apprenticing under a master jeweler and what it's teaching me about craftsmanship, patience, and precision.

This week, marks 6 weeks since I started working with a master jewler and learning the ways of repairing and working on custom jewelery.

Why Jewelry?

My journey into craftsmanship started with woodworking, but I’ve always been drawn to the precision and artistry of jewelry making. When I got the opportunity to learn from someone with 40+ years of experience, I couldn’t pass it up.

The First Week

Day One: The Tools

I spent the entire first day just learning about the tools. The jeweler’s bench is like a specialized workshop in miniature - files, saws, hammers, mandrels, torches. Each tool has a specific purpose, and many have been in the shop for decades.

“These tools become extensions of your hands,” my mentor told me. “But first, you have to earn their respect.”

Days Two-Three: Basic Techniques

I learned to saw straight lines in silver sheet metal. Sounds simple, right? It’s not. The saw blade is thinner than a hair, and it takes a delicate touch to keep it from breaking. I went through about a dozen blades before I got the hang of it.

We also worked on filing - removing material to create smooth, even surfaces. The goal is to achieve a mirror finish through progressively finer files and sandpapers. My forearms were sore by the end of day three.

Days Four-Five: My First Piece

By the end of the week, I was ready to make something: a simple silver ring. Nothing fancy - just a band with a hammered texture. But it was mine, from start to finish.

I cut the silver strip, filed it true, formed it on a mandrel, soldered the seam, shaped it to size, applied the texture with a ball-peen hammer, and polished it to a shine.

It took me six hours. My mentor could probably do it in twenty minutes.

Lessons Beyond the Bench

Precision Over Speed - “Slow is smooth, and smooth is fast,” my mentor says constantly. Rushing leads to mistakes, and mistakes in precious metal are expensive.

The Value of Experience - Watching a master work is like watching poetry in motion. Every movement is deliberate, efficient, and informed by decades of practice.

Transferable Skills - Interestingly, my background in software development helps. Debugging is debugging, whether you’re hunting down a bug in code or figuring out why a solder joint won’t flow.

Working with Your Hands is Meditative - There’s a flow state that comes from focused handwork. It’s different from coding, but equally satisfying.

What Surprised Me

The level of precision required is astounding. We’re working in fractions of millimeters. A ring that’s 0.2mm too tight won’t fit. A bezel that’s 0.1mm too tall won’t set properly.

Also, the physical demands. My hands, wrists, and eyes are tired in a completely different way than after a day of coding. Good lighting and proper posture are critical.

Looking Ahead

I’m only one week in, but I’m hooked. Next week, I’ll learn about stone setting and start working with gold. The journey from software developer to craftsman continues to evolve in ways I never expected.

Whether I’m writing code or shaping metal, it’s all about precision, patience, and creating something meaningful with your own hands.

More updates to come as I continue this apprenticeship. For now, I’m going to ice my hands and practice more filing.

More Like This

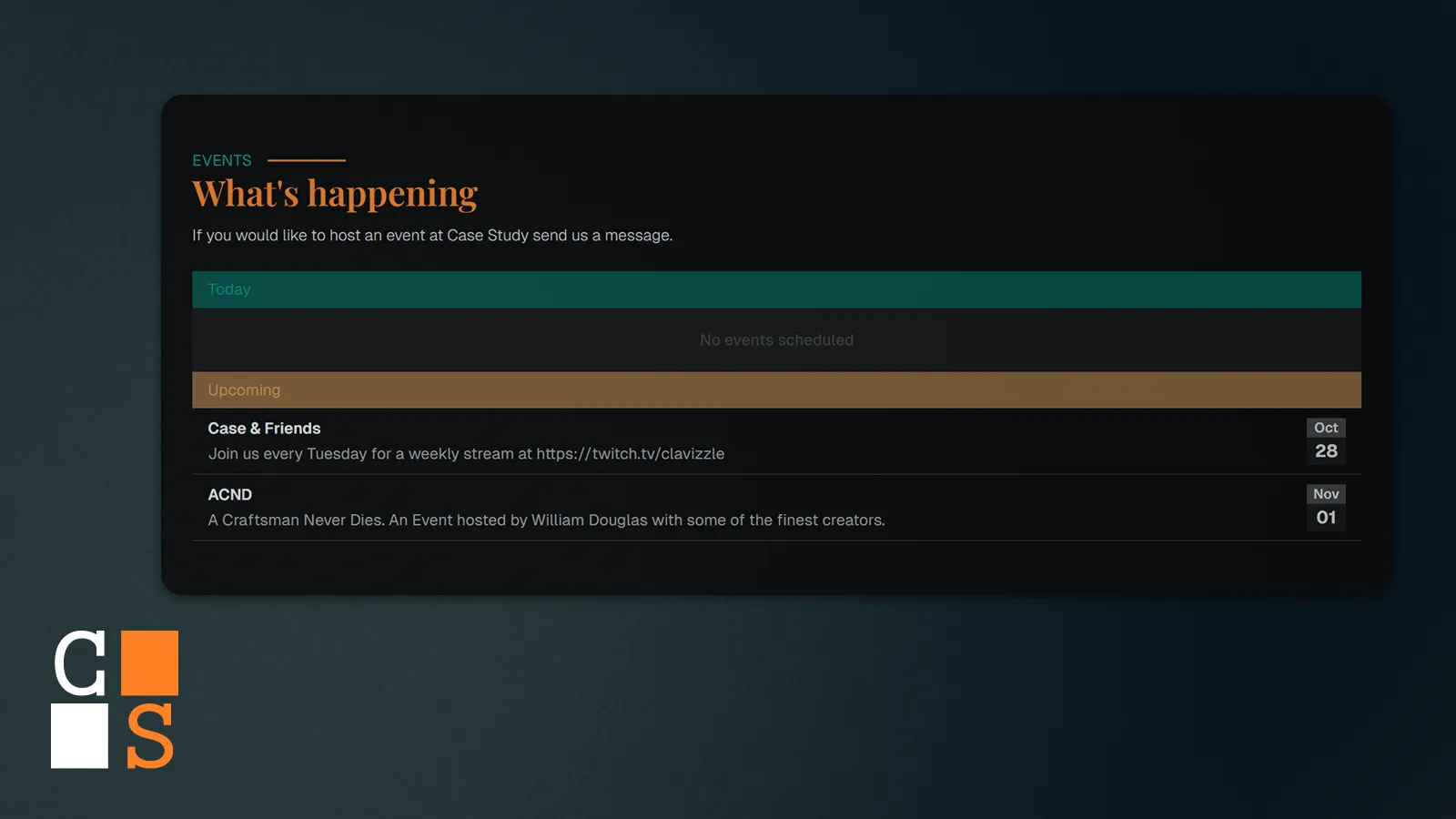

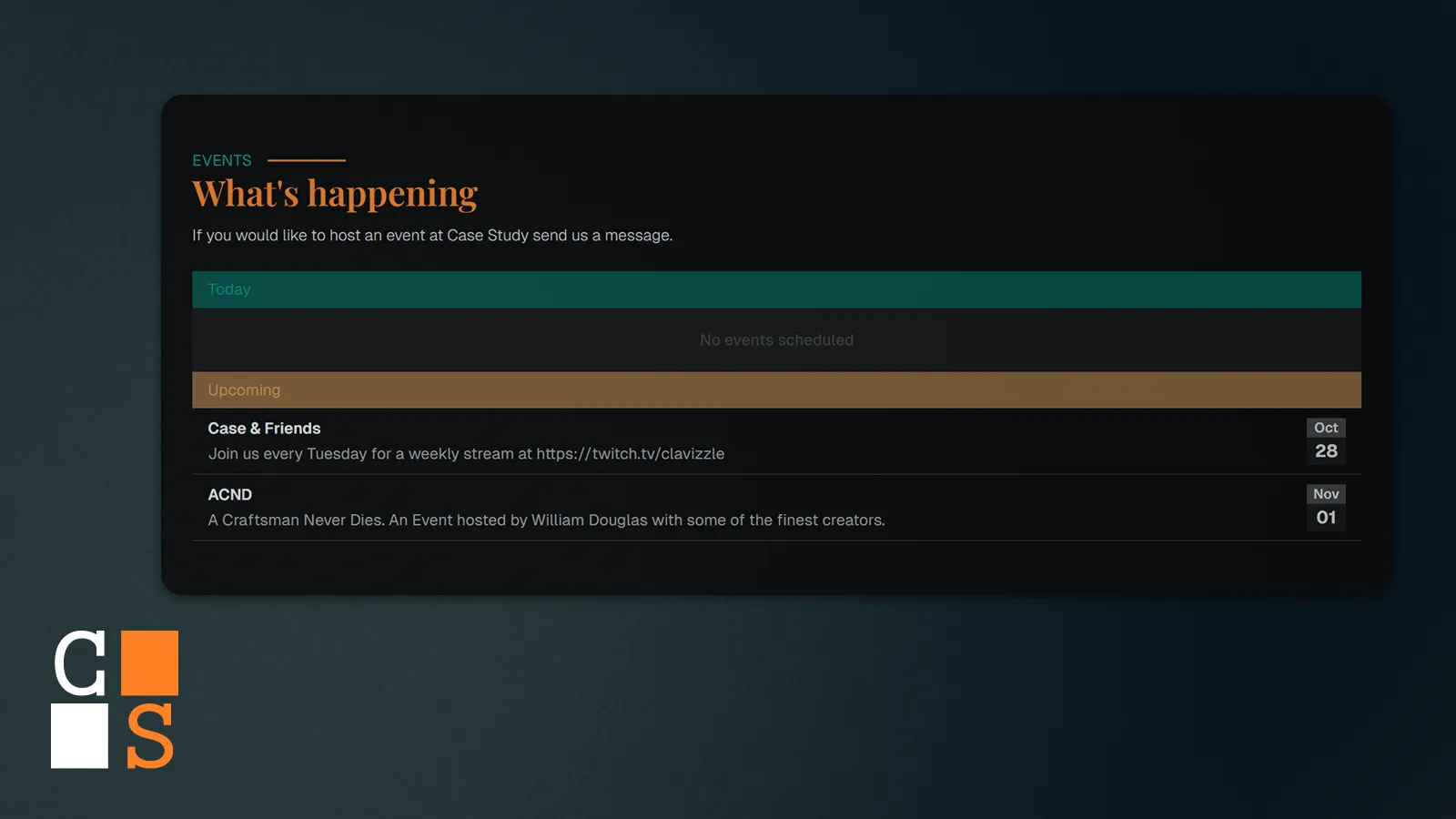

Building a Dynamic Events Component for a Coffee Shop Website

How I built a system to show recurring events at a coffee shop.

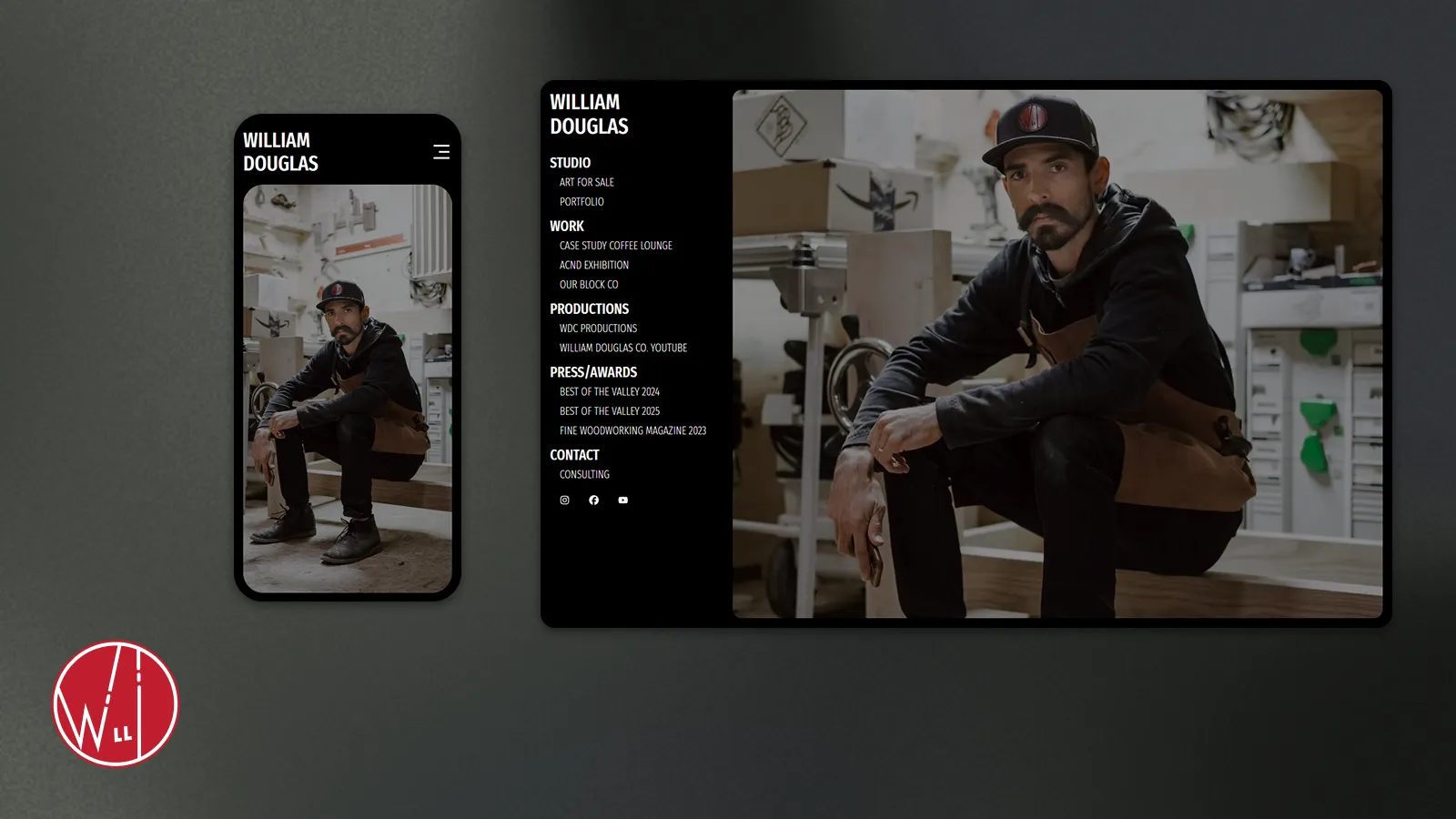

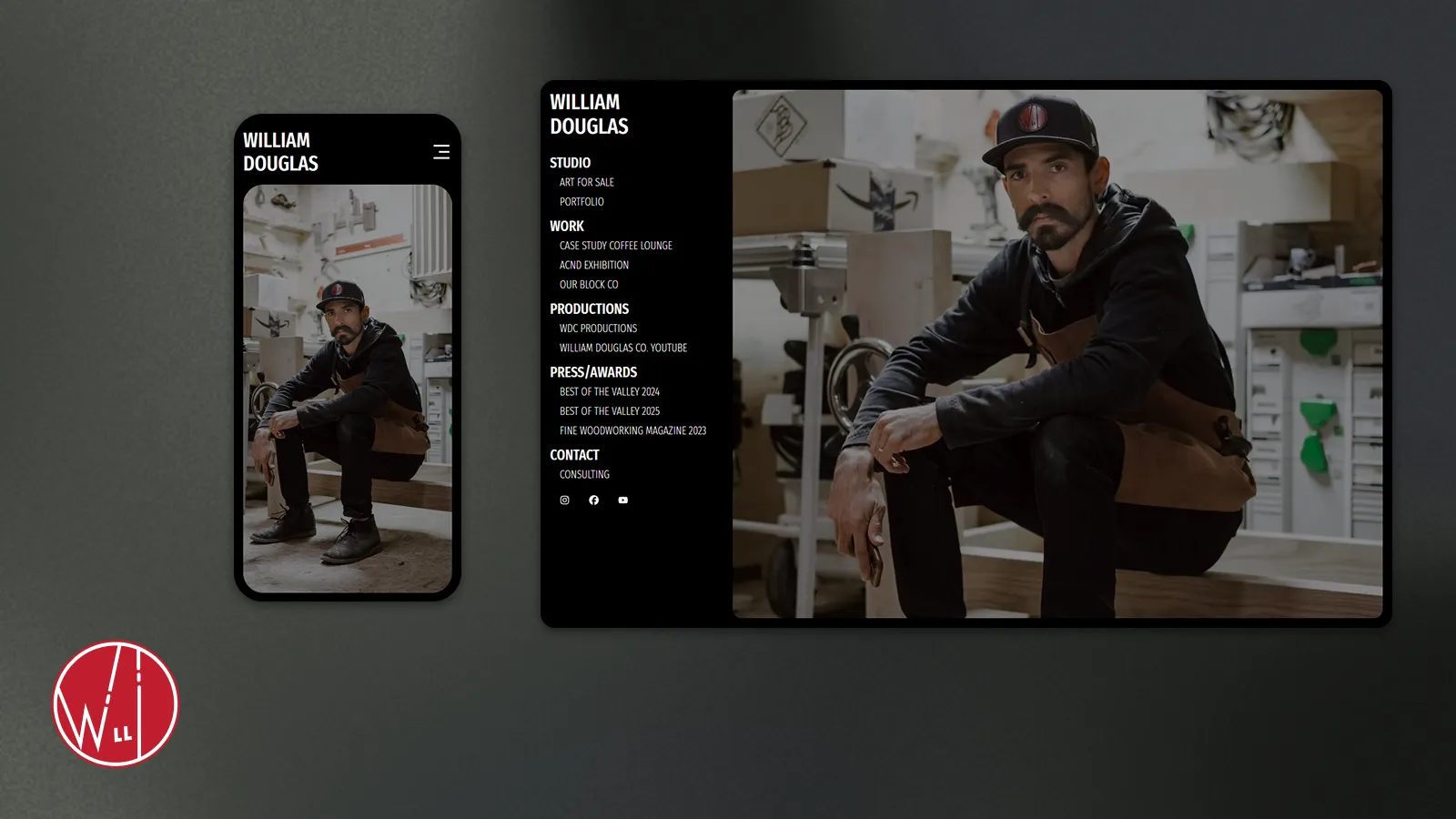

Creating an Interactive Menu System: A Real-World Solution

Explore how I designed and built an interactive menu system using Next.js, Tailwind CSS, and Framer Motion. This case study demonstrates creative problem-solving and polished user experience across desktop and mobile devices.